Archive for April, 2012

Self Leveling Floor Compound: A Compound Solution

A Self Leveling Floor Compound Could Be the Answer You’re Looking For

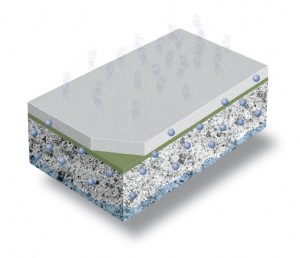

Anywhere one enters a building we often see floors that are not quite as flat as the builder may have wanted them. Or, the various hills and valleys of a floor may simply be due to the building having settled ever so slightly, or it may indicate bigger problems. Utilizing a self leveling floor compound is best for leveling bumpy concrete floors or even wood floors that may be no longer level due to the floor joists having flexed or twisted in time. These modern self-leveling compounds are superlative for smoothing out the various dips encountered in either a concrete floor or even a wood subfloor.

Of course any application of a self-leveling floor compound requires that the subfloor is first of all stable and finally spotless. No floor compound will add stability to the floor, thus if need be floor joists may need to be either replaced or strengthened first.

It also stands to reason that the entire subflooring must be spotless. Dust accumulation especially will prevent any floor compound from adhering to the subfloor, so proper preparation by the flooring contractor is essential.

It is always interesting to watch such self leveling floor compounds being laid, however most of the time the first layer is nothing more than a primer. The primer then must be allowed to dry first before the self-leveling floor compound is introduced. The primer simply allows optimal bonding for the floor compound, very similar to a paint primer. However, this is one more step in the process, and time is money.

Things get a bit more interesting now, as the installer seeks and finds all of the lower levels of your flooring. There are numerous ways of doing this, but all of them are interesting to see. The installer will fill in those “holes” first since all of these compounds set up extremely quickly. If ever you’ve wanted to see a worker work fast, this will definitely be it. The self-leveling floor compound usually only has a “work life” of about 10 minutes, and thereafter it truly cannot be worked as it has begun to harden.

Or you might call Silikal to begin with. Because the Silikal floor product is put on while it is a liquid, in essence the product is its own self-leveling floor compound. In addition, you will not need to spend all that time allowing for a primer to be laid and worse yet to have to dry. Keep in mind that once Silikal is laid, the entire area is then ready to be walked upon or even driven upon for it cures in less than one hour – it’s that strong!

Kennel Flooring Options for Dog & Cat Lovers Alike

Kennel Flooring Options: A New Face In Kennel Flooring

Probably the first thing you will run into if you are considering kennel flooring options will be rubber flooring. Now rubber flooring is frequently found in kennels as well as doggie day care facilities. Such flooring is superbly easy to put down, as no adhesives are even needed to install. Such rubber flooring is often sold in 5mm x 48″ x 50ft rolls, or in ¼” or 3/8”. Thus as you can see there are different thicknesses available, but all in 50ft rolls. The negatives to such rubber kennel flooring options are that it is superbly easy for the dog to chew on the flooring. Next, nothing stops dog urine from running under these rubber flooring mats. Since the subflooring is undoubtedly concrete, the concrete itself will have dog urine entering into it, as concrete is a porous substance. The rubber flooring will have to be pulled up, and properly cleaned each time the dog urinates on it, or there will eventually be a terrible stench coming from the urine soaked concrete, and it will be impossible to remove the odor from said concrete over time.

Next if you keep looking at kennel flooring options you will find vacuum-formed, but very high density especially designed thermo plastic panels as kennel flooring options, and these are equipped with interlocking tabs so that you can make one large perfectly interlocked kennel floor. At least this material is definitely difficult for a dog to chew, but the subflooring is still going to get ruined as pointed out above. There are, however some rubber flooring options that when utilized for dog agility courses do make sense. This type of material gives the added benefit of better traction, shock absorption and joint protection for the dogs, as well as their trainers all while running and jumping but utilizing it for kennel flooring is not recommended moisture will find its way beneath the floor flooring.

Occasionally I run into someone who has chosen garden pavers as a kennel flooring option. There are a number of reasons why this is a bad idea. First they tend to settle into the ground making your flooring become very lopsided. Next weeds will be inclined to grow in between each one, and finally they will hold moisture such as urine, thus you will have to remove them and place them elsewhere after a tedious cleaning job.

Finally we arrive at concrete. Concrete is great for as far as dog kennel flooring options, however the concrete needs to be sealed properly. The best seal for this kind of flooring is Silikal. You see it forms a total unbreakable bond to the concrete, so that no dog urine, no small bits of fecal matter can ever penetrate it. It retains the dog’s warmth when laid upon, cannot be chewed off, and is totally without VOCs, thus it is entirely safe for your canine. One of the additional reasons why this is superlative flooring for a kennel is that it is both skid resistant and slip resistant too!