Archive for 2012

Restaurant Floors Concrete: How to Provide the Proper Protection

The Restaurant Floors Concrete Dilemma

99.9% of restaurant floors constructed today are surely made out of concrete, so when speaking of restaurant flooring, concrete figures predominantly in them. As to what goes on top of the concrete restaurant floors, now that’s the question that many restaurant owners need to face and question.

Some owners look at the restaurant floors concrete and envision being able to mix and match tiles with all manner of singular colors and thus being able to fashion appealing patterns on both the kitchen flooring and their restaurant flooring, The thing is that if a restaurant owner chooses tile, then they must make certain that each and every joint is properly sealed because grout can and will permit all manner of seepage and even allow food and other debris to lodge in those gaps between the tile. What happens next is that the grout begins to smell, and it changes color as well appearing dirty and filthy. There will also be dirty water seepage under the floor tiles, which will begin to pop out. Also, if not sealed, tile is incredibly slippery if either water or grease lands on it even if it is considered non-slip tile. Thus, if you see tiles in your mind’s eye, that’s fine but be sure and have Silikal seal the tiles so that you can rest assured they are properly sealed and will have slip resistance.

Other owners will see the restaurant floors concrete look and think that they need an older style appearance, and thus will want to put hardwood floors atop that concrete. The exact same scenario will happen with wood, as it needs to be properly sealed with Silikal in order to prevent water and grease seepage under that wood. Silikal not only does a perfect job at sealing, but it also brings out the natural beauty of the wood floor besides giving it a very eye-appealing polish.

Still other owners will look at the restaurant floors concrete look and envision stained concrete. Silikal can also do that, giving the floors in that restaurant exactly the “look” that the owners have envisioned for the perfect ambiance to take place. Be mindful that even stained concrete will need to have a concrete stain sealer applied. In addition to stained concrete, some owners have decided that they want the look of the floor to be stone or river rock flooring, some even opting for marble. “Real” marble of course is a terrible choice for a restaurant, as it stains so easily and is one of the most slippery of choices.

Silikal takes care of sealing all those, as well as creating a marble floor that only has the appearance of marble. Silikal is actually all those floors and more! With Silikal you can create the appearance you desire, as it is one of the greatest design elements available for restaurant flooring.

Industrial Resins & Chemicals In Today’s Acrylic Coating Technology

Industrial Resins & Chemicals: The Applied Science of Flooring

As we all know industrial resins & chemicals are now very widely utilized in order to enhance the actual performance as well as feats of today’s acrylic coatings technology. What’s interesting is that the very hardness and adhesion characteristics of acrylic polymers are what allow the amazing bonding to a miscellany of substrates. Combined with industrial resins & chemicals, acrylic resins have been able to replace the harsh chemical solvents that used to be in acrylic coatings. This has made great strides in being able to form and create environmentally friendly products.

Take the wonders of Silikal for instance. Industrial resins & chemicals have enabled the creation of Silikal flooring, which contains a number of startling attributes such as:

•Anti-corrosion properties

•Alkali-resistance

•Best storage stability

•Complete lack of VOCs

•Excellent gloss, finish and clarity

•Fastest curing possible

•Good quality, first-rate adhesion to non-porous as well as porous surfaces

•Improved pour of product

•Improved solubility

•Superior hardness

•Superb weatherability

There are all manner of different resins that have been developed in order to create water as well as corrosion resistance, gloss, adhesion and of course hardness. What has been developed is a modifier for both the alkyd and epoxy air-dry coatings. These coatings themselves were actually designed to improve the water resistance, gloss, adhesion as well as hardness that they are applied to.

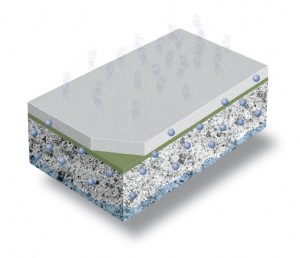

So many chemicals have made our lives so much easier. For example take fully flexible (elastometric) waterproof decking systems that are utilized in highly exposed areas to create totally waterproof traffic bearing as well as walking areas.

We are all thankful for the industrial resins & chemicals that have created Silikal floors that will last longer than the building they are installed in. Silikal is so waterproof that it has been utilized as glass to hold back millions of tons of water in huge aquariums. Silikal flooring can prevent freeze-thaw damage in the worst weather conditions possible on earth, yet is the same Silikal that can be introduced to flooring no matter the weather.

Keep in mind too that industrial resins & chemicals are what have allowed Silikal to be installed anywhere, and in one short hour the floor can be driven upon even with forklifts. Only Silikal cures that fast, and that completely. In addition, the Silikal flooring can be completely stain resistant, which makes Silikal so much in demand for healthcare flooring where blood, iodine and other stains can happen, as in hospitals.

Floor Coating System Supplier: Confidence You Can Count On

A Floor Coating System Supplier For You

There are of course large companies in the United States where one may shop for same, and in that instance companies such as Home Depot would be said to be the floor coating system supplier. However if you are a company who is seeking substantially more expertise from your supplier, we cannot discourage you one bit away from those handyman locales.

You are seeking a floor coating system supplier who has the industry experience to accomplish what you wish, and you want this supplier to not only be exceedingly knowledgeable about the product he represents, but he must also know all about the product quality so that he can actually meet your demands regarding a resinous flooring system. Some people would say that they are not interested in a sales pitch, but you definitely agree that whoever provides a true variety of fully durable, yet flexible flooring solutions for your particular highly unique applications should become the floor coating system supplier for your company.

Well, many will come and present their wares. Indeed many will come, but few will ever be chosen? That is part of our free enterprise system, don’t you know? Your particular floor coating system supplier should be able to handle all decorative, institutional and industrial needs, and thus be able to offer specific polymer flooring as well as coating needs to your company thus providing an assortment of flexible, yet durable solutions for a huge variety of tremendously unique applications. The point is that your floor coating system supplier should be able to provide you with solutions that are truly based on your specifications that include: conductivity, thermal shock resistance, its impact as well as its wear resistance, and of course even its chemical resistance. Finally such a supplier should be able to answer direct questions even about the moisture vapor tolerance of such a floor, but then there is also being ultra cognizant of such things as color and the final appearance of your flooring.

In essence a good floor coating system supplier should be able to not only answer all the questions you may have on the subjects above, but needs to also be able to ascertain your needs on his own even. This is partly why Silikal is considered the foremost floor coating system supplier in the entire world. Their people know and understand Silikal with a deep dedication that shows the moment you contact that supplier. You will not do better than with Silikal, we guarantee it.

No Slip Condition Flooring: Whats Beneath Your Feet?

No Slip Condition Systems Set The Stage for Safety

There are some floors that absolutely need to be in a no slip condition. Examples might include a butcher shop, a dentist office, a hospital, public showers, bathrooms, auditoriums, kennels, actually the list is totally endless, as to how many businesses and commercial establishments need a slip resistant flooring system.

No slip condition is also a theory of engineering or fluid dynamics. It relates to viscous fluids and boundaries thus limiting how much particles can move. Further along with these studies are insurance studies that have recommended that due to the American Disabilities Act (called the ADA) walkways, ramps, and flooring in the food and beverage industry must have a friction level of .60 or more for flat spaces and .80 should the floor be ramped.

OSHA has not gone quite as far, and required that floors should actually have a friction level of .50 OSHA is of course the Federal Agency called the Occupational Safety and Health Administration whose job it is, is to oversee and enforce safety and heath legislation here in the United States. There are even slip meters, which will allow someone to perform the static coefficient of measuring friction.

Silikal the world’s leader of concrete sealer flooring has delved deeply into the no slip condition, and in fact everyday their scientists are working on this problem, ascertaining that the Silikal product not only adheres fully to OSHA standards, but also surpasses them highly. It is important for anyone seeking no slip flooring to know and understand that the Silikal non-slip flooring is actually one of a kind. Above all Silikal installers are very adept at matching the non-skid coats to the floors, knowing exactly what to do when it is needed for extreme non-slips, as opposed to mild non-slips.

It is often said in the non-slip business, that Silikal is the only name that one should trust if an establishment wishes to completely avoid hazardous slip and fall accidents. Other businesses, property owners, architects, builders, and building managers have relied on Silikal for years to meet their full legal obligations to ensure that the floor surfaces that employees and the general public utilize are fully non-slip. Over and over again, courts have upheld that Silikal non-slip flooring offers the maximum protection against injuries that come from slip and falls.

If you are among those listed above, builders, building managers, etc. who feel that their businesses deserve the same high durability protection that will halt costly litigations that arise from injuries, then be sure to call on Silikal flooring. Silikal can offer peace of mind besides beautiful flooring!

Self Leveling Floor Compound: A Compound Solution

A Self Leveling Floor Compound Could Be the Answer You’re Looking For

Anywhere one enters a building we often see floors that are not quite as flat as the builder may have wanted them. Or, the various hills and valleys of a floor may simply be due to the building having settled ever so slightly, or it may indicate bigger problems. Utilizing a self leveling floor compound is best for leveling bumpy concrete floors or even wood floors that may be no longer level due to the floor joists having flexed or twisted in time. These modern self-leveling compounds are superlative for smoothing out the various dips encountered in either a concrete floor or even a wood subfloor.

Of course any application of a self-leveling floor compound requires that the subfloor is first of all stable and finally spotless. No floor compound will add stability to the floor, thus if need be floor joists may need to be either replaced or strengthened first.

It also stands to reason that the entire subflooring must be spotless. Dust accumulation especially will prevent any floor compound from adhering to the subfloor, so proper preparation by the flooring contractor is essential.

It is always interesting to watch such self leveling floor compounds being laid, however most of the time the first layer is nothing more than a primer. The primer then must be allowed to dry first before the self-leveling floor compound is introduced. The primer simply allows optimal bonding for the floor compound, very similar to a paint primer. However, this is one more step in the process, and time is money.

Things get a bit more interesting now, as the installer seeks and finds all of the lower levels of your flooring. There are numerous ways of doing this, but all of them are interesting to see. The installer will fill in those “holes” first since all of these compounds set up extremely quickly. If ever you’ve wanted to see a worker work fast, this will definitely be it. The self-leveling floor compound usually only has a “work life” of about 10 minutes, and thereafter it truly cannot be worked as it has begun to harden.

Or you might call Silikal to begin with. Because the Silikal floor product is put on while it is a liquid, in essence the product is its own self-leveling floor compound. In addition, you will not need to spend all that time allowing for a primer to be laid and worse yet to have to dry. Keep in mind that once Silikal is laid, the entire area is then ready to be walked upon or even driven upon for it cures in less than one hour – it’s that strong!