What Is Monolithic Floor Coating You Ask?

Look No further for Answers To What Monolithic Floor Coating Is

You may have heard this term bandied about but, perhaps you are not sure what monolithic floor coating refers to, or what it means. The word monolithic was first used to describe a geological feature such as a monolith; for example a mountain might be associated with the word. Archeologists use it to describe columns saying that there was a monolithic column found in Greece, for instance, when they meant that the column had been made all from one stone only. In today’s vocabulary it means that it is something that is unbroken, one piece, and therefore unfragmented.

Now you understand better that a monolithic floor coating will have no seams and thus no joints. Unlike say a tile floor that is in many pieces with grout in the middle of each adjoining tile, tile floors are definitely not monolithic floors.

Floors that are not monolithic can allow dirty water to seep between it and the substrate, a substrate meaning what’s under the floor or in some construction dictionaries define it as a structurally stable material. In many cases, the substrate is actually poured concrete, but imagine what nasty germination can take place in that instance? First, there would be germs, bacteria, even fungus, potentially followed by growing mold. Chances are that the floor’s condition would occasion strange appalling and ghastly odors. Let’s assume for instance that perhaps our non-monolithic floor is in a restaurant where spills are part of the business. How is one to clean a floor that sucks up spills?

The bacterial count of food waste alone is downright staggering, yet many restaurants utilize those old-fashioned safety rubber mats. Those need to be scrupulously cleaned then hung out to dry every night, and the floor then needs to be mopped with strong chemicals to try to stop the germination that very likely will still be taking place on the substrate.

Now you can see and understand the importance of a monolithic floor coating, it’s one that will not allow materials of any kind to penetrate it. Now, Silikal is the finest monolithic floor coating available anywhere in the world. The reason is that they have a exceedingly secret ingredient that their own scientists have created especially for Silikal. It is called MMA which is what is always in monolithic floor coatings, however because of the secret ingredient, their formula is what they call “enhanced” MMA. MMA, by the way, is Mixed Martial Arts to lots of martial arts fans, but in flooring it stands for Methyl Methacrylates, thus a mouthful that’s been reduced to MMA.

The “enhanced” portion of Silikal’s enhanced MMA enables a business to even drive heavy forklifts on the new floor with only one hour of “curing” which is the technical word used to mean “harden.” Now, if you don’t have forklifts in your business, perhaps you have cars that you need to drive into the mechanics, or perhaps you have a huge amount of foot traffic, all of which can use the new floor just one hour after it has been laid by the highly qualified technically trained workers.

What Silikal’s enhanced MMA does is to stop the product from making pinholes, which unfortunately MMA that has not been enhanced will make. In addition MMA that is not Silikal’s enhanced MMA will also go through chemical absorption that will also cause it to separate from the substrate. Only Silikal flooring will remain whole or monolithic for the entire life of the building.

Non Toxic Concrete Sealer And The Benefits Hidden Inside

Concrete Sealer And The Non Toxic Application Benefits

Looking for a concrete sealer non toxic especially? Maybe your basement walls seem to feel damp during the wet months, or even the floors? Perhaps there is even a moldy smell? You may even require a concrete sealer non toxic type on your patios, sidewalks or driveways which; especially if you live up North, will have freeze and thaw damage. Your concrete walls that have that white powder efflorescence coming though probably have worried you, and rightfully so.

You see concrete, although rock hard if you hit your head on it, is actually porous. Thus it absorbs water, much as a sponge does. If you have used some concrete sealers on it but the problems have come back, chances are that that’s because the seal was not perfect, and only the surface looked sealed. You will want a sealer that permeates deep and sets up hard all through the pores of the concrete and is so well sealed that there are not even pin pricks through your concrete sealer non toxic.

Imagine if you can, a zoo that needs to create a pond for some of its animals. The pond has to of course hold water, and not leak, especially not into the next exhibit! The very type of permanent, completely non-toxic concrete sealer they would use is what you require.

In addition, this product has to have absolutely no VOC’s (odor) so that you do not bother the other animals, nor any visitors with the noxious odors that some products of this type have. VOC, by the way stands for “volatile organic compound” and if ever you have smelled one, you know how that noxious smell can knock you off your feet!

About the only concrete sealer non toxic that fits into the description above plus has many other wonderful qualities is of course Silikal. Silikal will be permanent, and will totally seal the pores of the concrete to which it is applied. It has absolutely no VOC’s, meaning no odor at all, and it seals concrete so well that not even a pinhole can suddenly appear in it. Non toxic concrete sealer completely adheres to the concrete for all time. In addition, it is completely seamless, and can be installed and utilized within one hour of installation.

Further, Silikal is not only tremendously functional but it is also quite beautiful. There is a rainbow of colors that it can be installed in, so that it can mimic rocks or hold the blue of the sky in its presentation. This is the same product currently utilized at the Georgia Aquarium, where the acrylic, which is 17 times stronger than glass, is currently holding back millions of gallons of water there!

Floor Trench Systems – An Innovative Design for Safe Sanitary Flooring

A Floor Trench System Installed Means An Easier Work Life And Clean Environment For Your Business or Facility

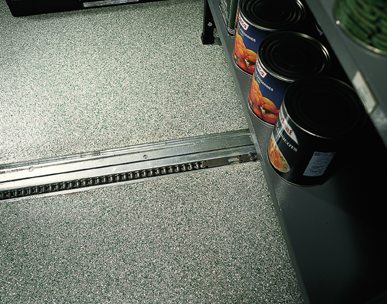

First let’s cover what floor trench systems are. If you have ever been in a commercial pool, you know that the water laps over into a trench system as people make waves. Well a floor trench system is similar to that in that it acts as an overflow. There are many businesses that need floor trench systems, such as water plants, waste-water plants, power plants, parking areas, chemical applications, and food processing as well as pharmaceutical applications. You will also find them on hardscape areas, around swimming pools, athletic facilities, and tracks.

They are also found in vehicle maintenance facilities, auto dealerships, garages, gas stations, kennels, marinas, schools, hospitals and fire stations to name a few more. In addition, they really come in handy for manufacturing plants, wineries, resorts, water parks, airports, rail stations, ports, and highway rest rooms. Thus you will see the floor trench system in just about every business possible, including sports arenas, stadiums, jails and prisons as well. They are widely utilized anywhere where water may make the floors slippery, no matter the source of the water.

The thing is that they are built right into the floor utility chase. The designers that pour the concrete for these, take into consideration things such as load bearing strength, its hydraulic capacities, the chemical resistance of the product utilized to go onto the trench system as well as the structural technology to be sure that the trench drain is correct for its particular application. Thus when it’s done, these floor trench systems are an enhanced process for removing any surface liquids for nearly all applications.

The “trick” was to find a seamless, totally non-porous, internal surface in order to further enhance the flow within these concrete floor trench systems. However, one company stands out above all others, and that is Silikal.

You see, Silikal has designed industrial floor coatings that are an amazing floor covering. It is especially treated to set up within one hour of application, and the end product is reactive, in that it will not allow bacteria nor mold to grow on it, within it, or even under it. This Silikal flooring is also made totally safe since it comes with slip resistance and of course, amazing clean ability.

You will find Silikal utilized in a majority of high-end restaurants where the kitchen is a beehive of constant activity and there is often floor trench systems associated with them to carry any foods away that might be dropped, and liquids as well, thus preventing a calamity in the kitchen should someone slip. When the cleaning crew shows up after a day’s worth of heavy duty cooking to clean the kitchen, they need not utilize strong detergents as everything can be cleansed easily as the floor trench systems in these establishments carries down all that waste water immediately and none of it remains in the trench. All is immaculate once more.

Laboratory floors as well are treated with Silikal and floor trench systems since their lab products will not put down any long-term damage on their Silikal floors. The reason is that Silikal floors are also

highly resistant to many tinctures, acids, greases, salts and many other laboratory solutions.

Why Commercial Epoxy Flooring?

Why We Use Epoxy Flooring in Commercial Buildings

Commercial epoxy flooring needs to be different than say residential epoxy flooring, as it will undoubtedly take a lot more punishment than it would inside a home. Take for example commercial epoxy flooring that is used in a garage where automobiles are repaired. First of course, there is the weight of the cars, the hot engines, the oil, the friction of their tires against the epoxy, and perhaps worst yet those dropped tools that fall out of a mechanic’s hands that with ordinary epoxy will gouge the flooring.

Or consider the commercial epoxy flooring that has to be put down at a kennel. This flooring needs to be hermetically sealed, as dogs will have sharp nails against the flooring, and unfortunately there will be both excrement as well as urine to deal with. If the commercial epoxy flooring is not properly sealed, even one tiny little pinhole would allow a plethora of germs and bacteria to grow underneath the floor resulting in malodorous smells and even encourage infections in their dogs. This is why, for instance, that tile is a very bad choice for a kennel. Tile means that there is grout, and grout will allow said germs and bacteria to grow at an alarming rate.

Then consider what hospital flooring must be like? They of course need to have flooring that is always extremely clean and of course the “right” floor is extremely helpful as far as infection control is concerned. Patients are already injured or in need of extreme care, and the workers need to be kept safe too, thus any commercial epoxy flooring utilized in a health care facility, hospital, or operating room needs to be completely slip resistant for both workers and patients.

Because, again we are referring to commercial flooring and not residential flooring, said flooring needs to be able to take a beating. Foot traffic is very hard on any epoxy flooring, thus it is imperative to find flooring that can “take” that kind of high foot traffic, such as a busy airport runway corridor, or the area where those taking an elevator or escalator would exit in a commercial store. Combine foot traffic with chairs on rollers, for instance as is found in side a laboratory, and that flooring needs to be the best it can be to take that without causing damage.

There is only one product that will adequately fill all the needs outlined above for a commercial epoxy flooring and that is Silikal. Amazingly, it will even set up within one hour so that no business needs to close for two to three days while the flooring dries! Created by Silikal years back, Silikal has had a chance to prove how long it will remain in service looking as if it had just been installed, and that length of time is positively amazing, for Silikal floors will outlast the buildings they are found in!

What makes Silikal so special? It’s the fact that it is made with enhanced MMA. The name of MMA is known as methyl methacrylate, but Silikal is the only company that has brought it one step closer to amazing by enhancing it. Yet it still retains its properties that enables it to be a no VOC flooring. That means that there are absolutely no malicious vapors or odors to contend with as it is being applied.

Can Your Business Afford Not To Have A ‘Hygiene Critical Flooring System’?

What Makes A Hygiene Critical Flooring System Necessary For Your Business Needs

Put simply good hygiene means clean. Thus, there are number of businesses we can imagine that are hygiene critical and thus need hygiene critical floor systems. The first place that comes to my mind is an operation theater. Thus it should surprise no one that many of our hospital floorings throughout the world have utilized Silikal as their flooring system of choice.

A good part of having a hygiene critical floor system is that it cannot in any way or manner ever harbor molds or bacteria, and it must be totally soil resistant. In essence then the entire flooring must not allow anything to penetrate it. Hence the use of strong acids as well as alkalines in any concentration can have no effect on that flooring, even if given extended exposure. Various coloring chemicals, as well as solvents such as acetone, will not be able to produce any stains, nor any discolorations. There cannot be any surface damage to deal with, therefore the product will be extremely safe to use in various laboratories where these chemicals may be dropped onto the floor system. Silikal meets all those requirements and more.

Load resistance can be important even in hygiene critical floor systems, making the goal of any floor system is for the floor to be able to sustain a 5’000 kg powered forklift truck having either one or perhaps two steering wheels by a typical case. The floor system should be able to sustain no damage whatsoever one hour after installation of the flooring system. Silikal meets all these requirements as well.

Users of such products as hygiene critical floor systems insisted that the interior designers and the architects could utilize Silikal in ways that would be unique and very attractive. Knowing this, Silikal even has a see through product that enables any company to emblazon their logo on the flooring system, making the floor extremely unique and giving freedom of design to the interior designer and/or architect.

The reason why hospitals and the like love Silikal flooring is that it is one of the most hygienic flooring choices due to the fact that it is not only

totally seamless but it is also completely non-porous, meaning germs and bacteria have nowhere to stick to, and nowhere to go either. It could not be more perfect. The non-porosity of the flooring also means that it’s superbly simple and easy to clean no matter what gets on it.

In addition their hygiene critical flooring system is completely resistant to thermal as well as mechanical deformation, thus it works well in extremely hot situations, as well as freezing situations. Silikal fits well as hygiene critical floor systems when a pharmaceutical product research and development company needs flooring. A first-class hygienic industrial floor is the indispensable factor in their being able to achieve their highest quality production processes. That makes Silikal the very best choice for all possible hygiene critical floor systems.